Elva

Low-Voltage Electric Validation

TL;DR

How NERDS Computing collaborated with ODU Manufacturing to design and develop a modular, cross-platform cable validation system that automates wiring inspection, enables self-learning configuration, and delivers real-time diagnostics — reducing defect rates to zero and streamlining the entire manufacturing workflow.

About the Client

ODU Manufacturing is a global leader in electrical connection technology, delivering high-performance solutions that ensure the reliable transfer of power, signals, data, and media across a wide range of industries. Their connectors are used in medical technology, defense and security, energy systems, industrial electronics, testing and measurement equipment, and automotive applications — powering innovation in some of the world’s most demanding environments.

Challenge & Objectives

The primary goal was to reduce the defect rate in the manufacturing process by detecting wiring errors earlier and optimizing the overall production workflow.

The client needed an intuitive cable validation system that operators could use without extensive training. In addition to ease of use, the solution had to be self-learning, capable of automatically adapting to new product configurations and generating detailed diagnostic reports — including connection integrity, cross-wire detection, and wiring accuracy analysis.

Technical Solution

A key requirement was maximum flexibility — the system needed to support future feature extensions and third-party integrations without major rework. To achieve this, we designed a modular, scalable architecture that allows new components and tools to be added seamlessly, eliminating the need for complete rebuilds.

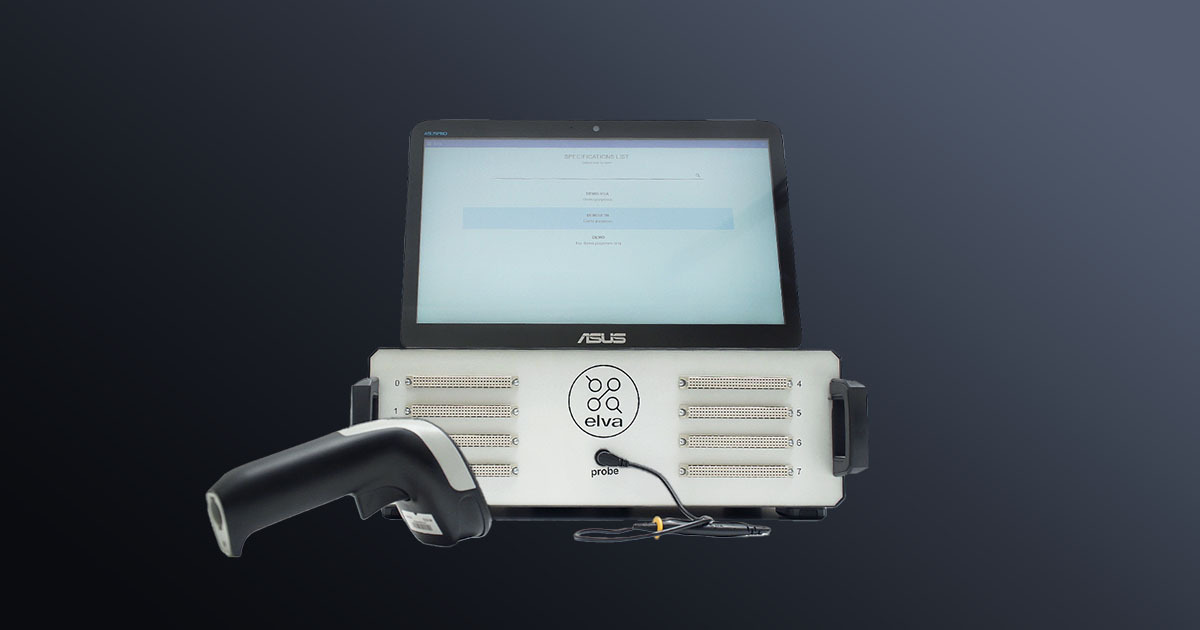

We developed a cross-platform application built with modern, widely adopted technologies, featuring an intuitive touch-screen interface, barcode scanner compatibility, self-learning algorithms, crossed-wire analysis, and multi-level user access. This architecture ensures both adaptability and long-term maintainability, supporting continuous improvement of the manufacturing process.

- Auto-Learn — automatically adapts to new cable configurations without manual setup.

- Test Mode — validates connections and detects wiring issues during production.

- Scan Mode — integrates barcode scanning for fast product identification and validation.

- Detailed Reporting — generates comprehensive diagnostics for connection integrity and cross-wire detection.

- Multilevel Access — ensures secure and role-based control across operators, engineers, and administrators.

Results & Impact

The implementation reduced the defect rate in low-voltage tests to 0, ensuring flawless wiring validation. By enabling instant detection of miswired connections, the system eliminated waiting time between product assembly and the high-voltage end-of-line quality check, significantly improving manufacturing efficiency and overall product quality.

More Materials

“The collaboration with Nerds was really good and open. We were continuously in touch regarding the ELVA project to have a great result.”